Peking University Third Hospital requested an accurate 3D model of a patient's spine and windpipe for an upcoming operation. There was a complication with the patient's windpipe due to illness and it was not possible for the surgeon to fit a tube through it and complete the operation. The hospital came to us looking for a model so they could practically evaluate different solutions.

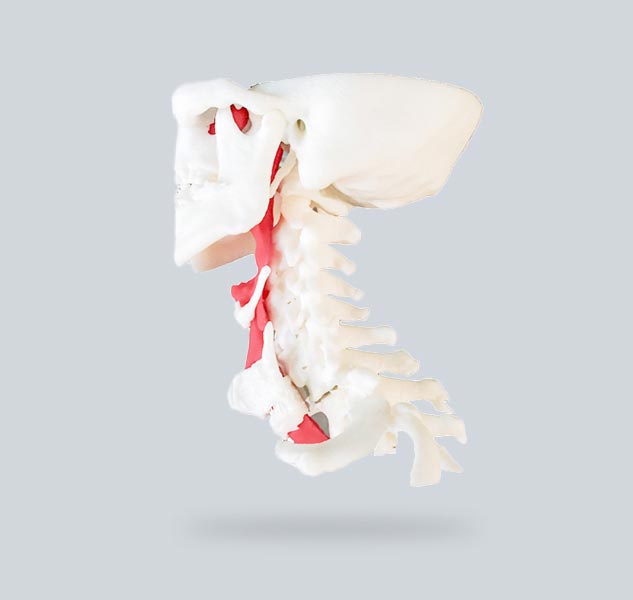

Hospital provided us with a CT scan of the patient's spinal area and required that all the detail included in the scan be represented in the final model. An additional requirement was that the windpipe should be made of soft material, with the rest of the model consisting of a hard material. They also preferred that the windpipe be made a different color from the other parts.

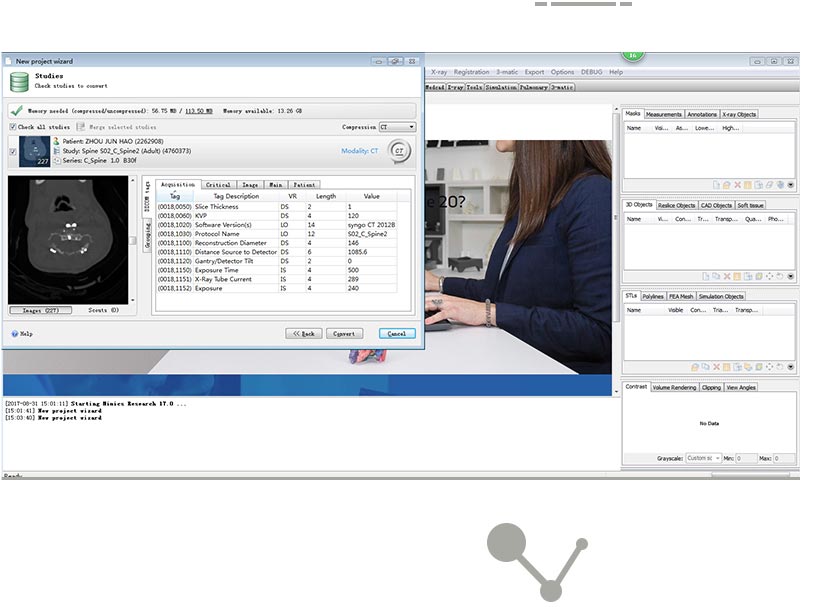

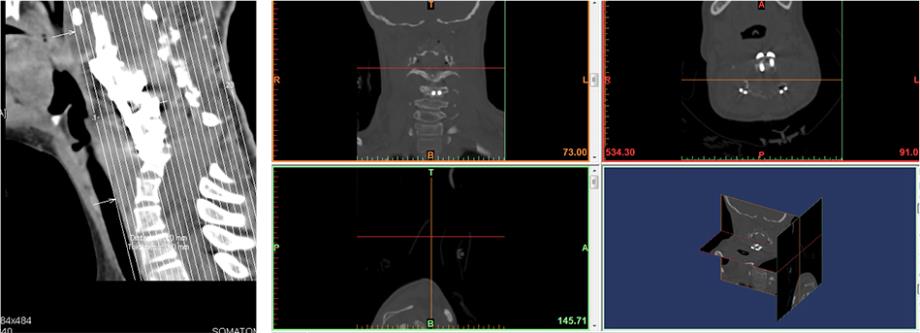

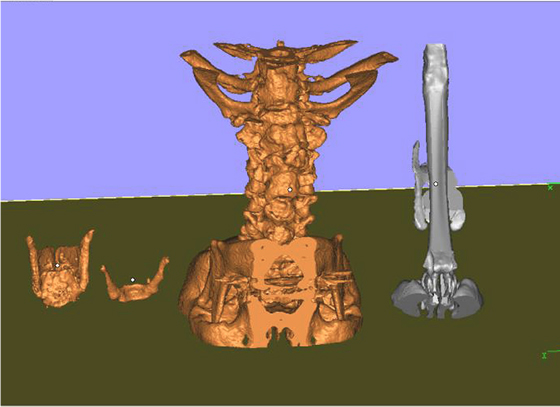

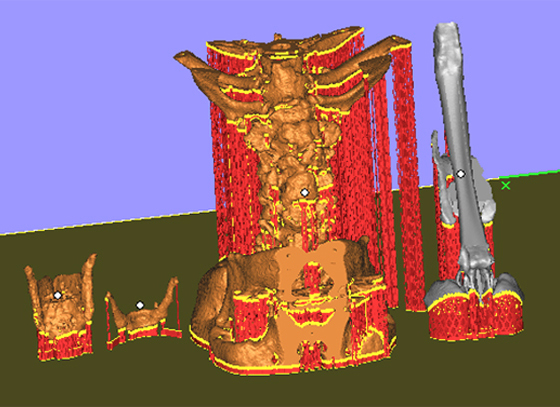

As this was a medical project, we imported the CT scan and NMR data into specialist medical software which is able to convert all the data into a 3D model.

Inside the software, we could see the problematic areas of the patient's windpipe

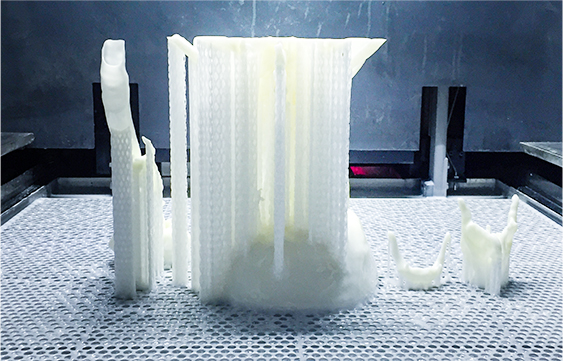

The next stage was printing itself. In medical projects such as this one, only an exact replica will do and the level of detail required is staggering. However, SLA 3D printing is more than a match for such complex shapes and structures, and with ProtoFab's skilled engineers on hand, every last detail was reproduced perfectly.

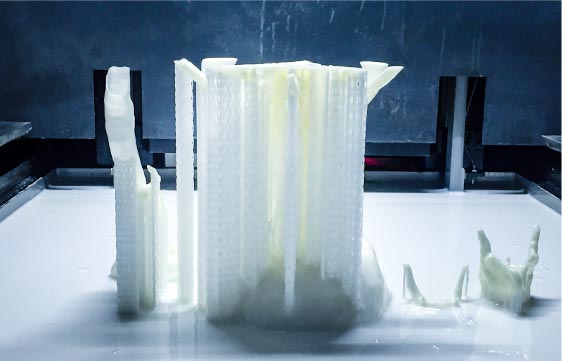

After printing the model was carefully removed from the printer and washed in alcohol. It was then time to remove the many support structures. In the middle image below the support structures are still in place, but the image to the right shows the final version of the model with the supports removed. There were no visible vestiges from this additional printed material and the client was very happy with the final result.

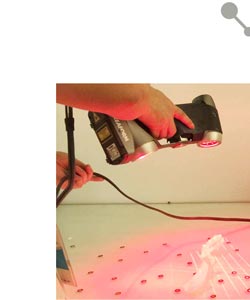

The hospital requested that the windpipe be made from a soft rubber material, as opposed to the hard material skeleton section. To achieve this, we first 3D printed a plastic model of the part. We then scanned it with a three-dimensional scanner and the results were sent back to the hospital to confirm its accuracy.

We then used this high-quality model to produce a silicone rubber mold. It was important that the 3D printed model was flawless as any imperfections would be carried over to the mold. With this mold, we could then produce the soft parts in different colors using vacuum casting.

With both sections complete, all that was left was to assemble them together. The finished model was delivered to Beijing No.3 Hospital and played a crucial role in patient’s operation. It allowed doctors to analyze a millimeter accurate physical representation of the patient’s windpipe and surrounding area in advance of the operation and gave them the chance to make preparations that would otherwise be impossible. After the operation was complete, the high-quality model has continued to serve a purpose in the hospital, giving students and trainee surgeons the opportunity to hold a specific case in their hands and see all of its complexities up close. For training purposes, such detailed models are highly valuable.

If you'd like to learn more about how ProtoFab can provide solutions for the medical industry, or if you have a project similar to the one described here, feel free to get in touch!