3D Printing - Car Grille Case Analysis

Product Name: Car Grille

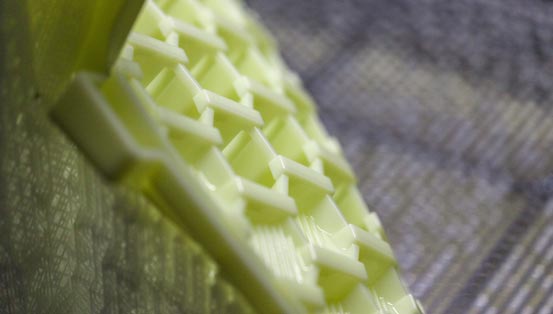

Process: SLA rapid prototyping + polish

Uses: design, structural verification, vacuum casting prototype

Manufacturer: Vistar3D printing

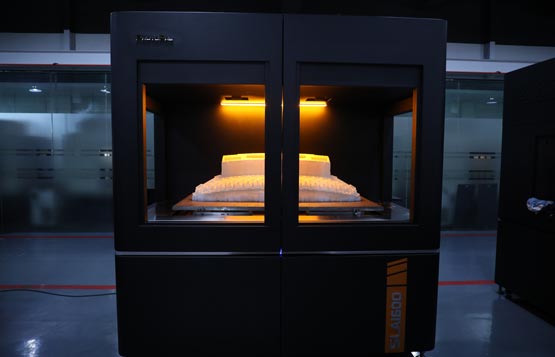

Printer type: SLA1600

Automobile grille, also known as "front face" and "grimace" of automobile, plays an important role in automobile design. In automobile, grille mainly plays an important role in the intake ventilation of water tank, engine, air conditioner, etc. It prevents the damage of external objects to the interior parts of the car while driving, at the same time, it also shows the beauty and personality. Today, we will introduce how Vistar applies SLA light-cured 3D printing technology directly to the overall solution of automobile, and realizes the innovation of automobile parts manufacturing mode.

Vistar

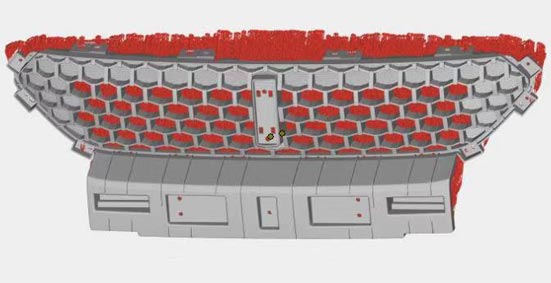

SLA1600 -Car grille One-piece printing

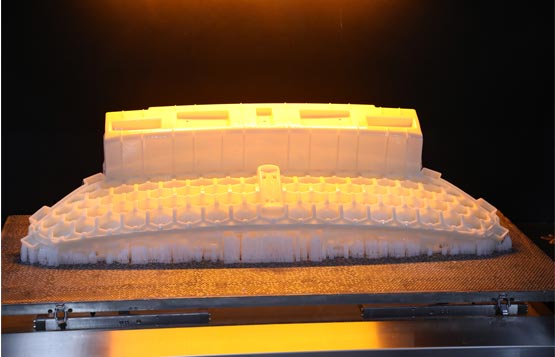

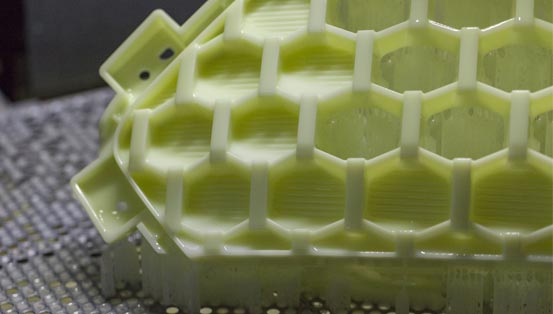

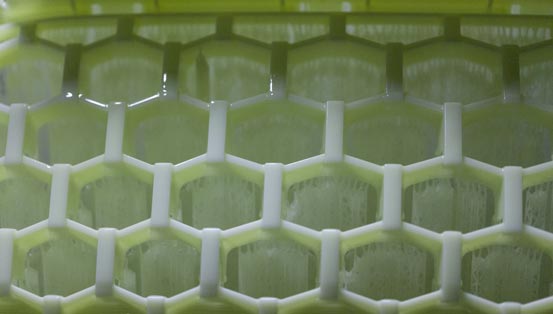

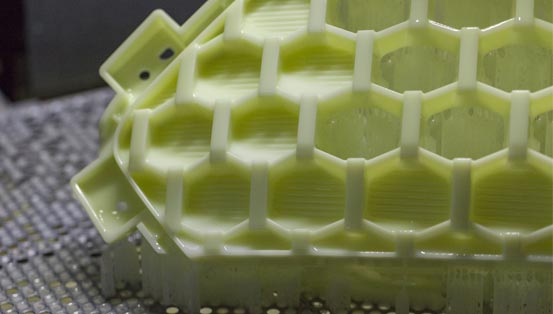

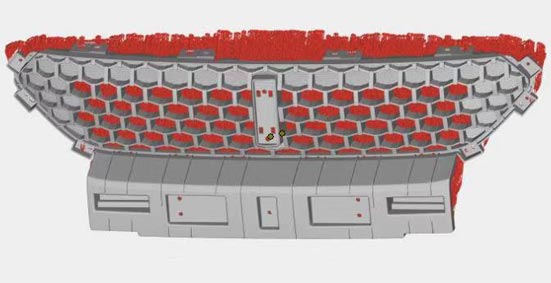

The structure of grille is very complex. Without mould, it is very difficult to develop it in the early stage, and it is almost impossible to realize it. However, Vistar’s 3D printing application solution can be printed and implemented as a whole at one time.

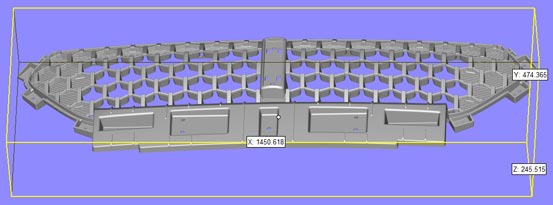

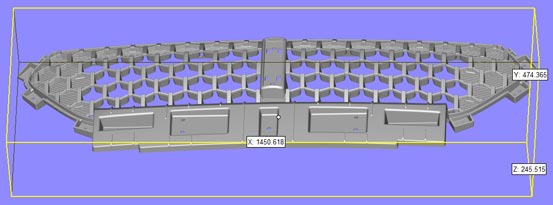

Grille Dimension

This 3D printing car grille is 1.45 meters long and is directly printed by SLA1600, a new high-efficiency intelligent 3D printing production system developed by Vistar. It adopts post-processing technology such as grinding and painting, and its error value is <1mm. Exquisite craftsmanship, the entire production process is completed in 3 days, shortening the development cycle by 80% compared with the traditional process, saving 70% labor cost and 49% production cost. This model can print large-scale products such as car grille, instrument panel, bumper, aircraft engine, real estate model, etc., which can effectively reduce the error and labor waste caused by splicing, and greatly improve product development efficiency.

Vistar -SLA1600 Equipment advantage

SLA1600 is a new ultra-large 3D printer developed by Vistar for the large-format demand of the Stereo lithography Apparatus (SLA) 3D printing market. It has a large printing format of 1600×750×550mm, which fully meets the requirements of the automotive, aerospace and other industries for large size. The need for lightweight components. Independent research and development of intelligent variable spot technology, three lasers, three scanners work at the same time, showing a surging power, the printing speed is amazing, printing car grille integrated molding takes only one day, four times faster than other printer brands. The four world's first technology makes the device smarter, more accurate and faster, and its product performance is far ahead of its peers.

Four global innovative technologies:

First, the Linux system: security, fast transfer speed, can automatically connect a variety of intelligent systems, free genuine operating system

Second, dynamic laser power printing technology DLC: printing speed increased five times

Third, the photosensitive resin material database and three intelligent printing modes: more convenient operation, greatly improved printing efficiency

Fourth, intelligent remote control functions: remote data transmission, remote visualization, remote management, intelligent new upgrade

ProtoFab SLA1600 Technical parameter table

ProtoFab SLA1600 Technical parameter table

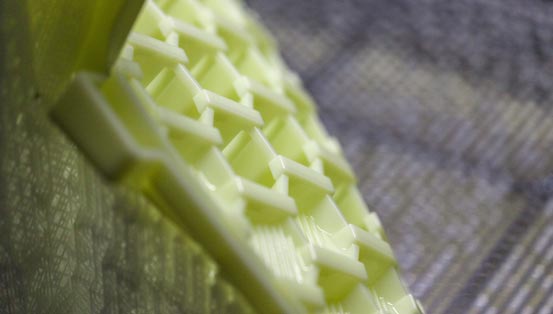

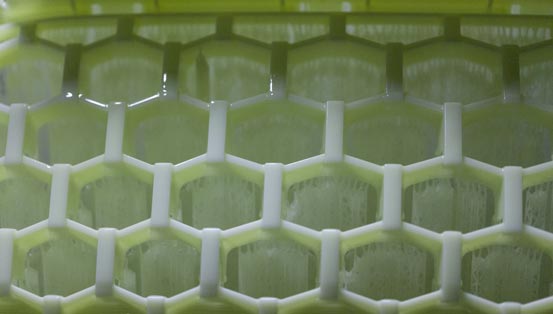

Excellent performance of printing materials

This automobile grille is made of photosensitive resin (which can be linked to material pages) developed by Vistar. It has the characteristics of high temperature resistance, high strength, dimensional stability and chemical stability. It has faster forming speed and good surface finish, perfect forming details, high precision, easy to do various post-processing, and is very suitable for precise assembly of automobiles, aerospace and aeronautics parts.

The printing material has good performance, high forming precision and smooth surface.

Finished product :

Conclusion:

The ProtoFab SLA1600's large print format provides a reliable and low-cost 3D printing solution for the automotive, aerospace and other industries. With the superior performance of the equipment and printed materials, the prototyping cycle of parts is greatly shortened, resulting in a much shorter part development cycle. The introduction of the SLA1600 breaks through the limitations of print size and will become faster, more flexible and more economical in the manufacture of automotive components.