Project Name:AVA BYTE Sustainable Indoor Garden Prototype

Materials:ProtoFab Formula L1 Resin

Production Technique:SLA 3D Printing

Printer Contracted:ProtoFab SLA600

Quantity:2 Sets

Lead Time:7 days

Good food is essential to life. AVA is the brain child of Valerie Song and Chase Ando, a former Chef, who met at Startup Weekend Vancouver in 2015. With the help of dozens of horticulturalists, engineers, and designers, they developed AVA Byte - a modern, space-saving smart garden that mimics nature to keep plants well-lit and watered, all year round. (http://avagrows.com)

Smart, Simple, Sustainable.

• World's Most Versatile Indoor Gardening Device.

• Automatic Self-Watering System.

• NASA-Inspired Plant Lighting.

• Soil-Free Nutrients.

• Drought-Proof Hydroponic Tech.

• Saves 90% More Water.

• Ready-to-Grow, Pre-Seeded Pods.

• Grows Plants 3x Faster.

• Grow Tomatoes, Herbs, Peppers, Lettuce, Berries, Microgreens,&more.

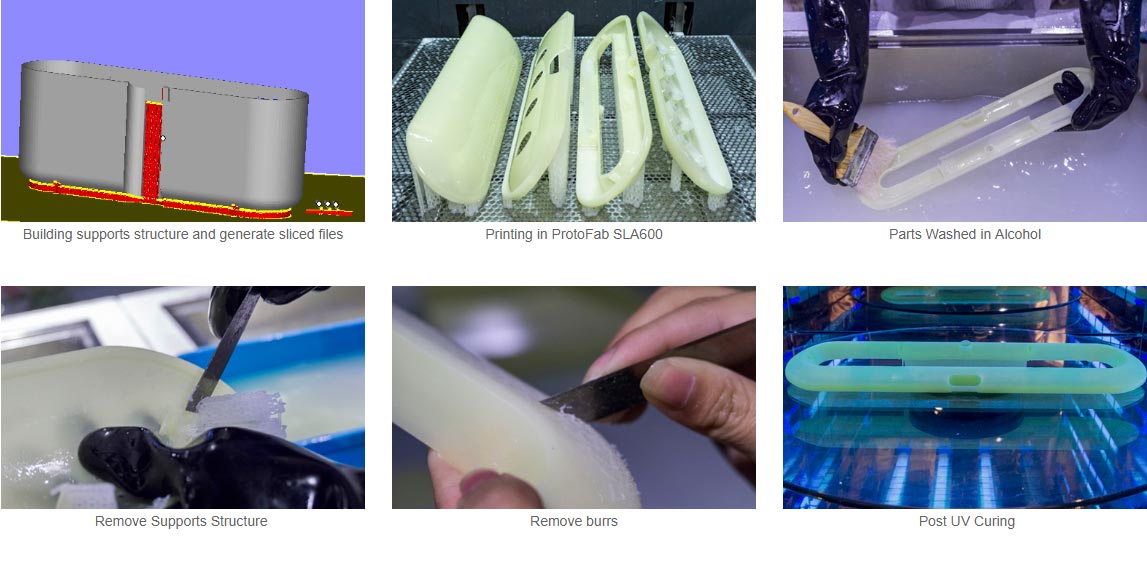

After analyse AVA’s CAD drawings and further discussion with customer we decided that SLA 3D Printing was the best technique to produce the prototype. Over 30 different parts can be printed out in our printing center with the fastest lead time. Our ProtoFab SLA600-3D Printer, with max. build capacity of 600 x 600 x 400 mm, was the perfect choice to produce these parts as the length of the bigger parts reached up to 532.6mm.

ProtoFab 3D Printing Production Center has over 55 SLA machines which allows us to build all the parts for this project efficiently. In order to make sure the parts are made with best quality, our team used professional building software to add necessary supports structure. One of the biggest part was built by 1759 layers. Thickness of each layer is only 0.1mm, ensuring highest precision and lowest surface roughness.

Post UV Curing

ProtoFab offers one-stop prototyping services. After initial post-curing in our printing center, parts are transferred to our dust-free painting workshop for sanding and painting. High-quality post processing is always the key to make product appealing.

Once all the parts are made the last step was to assemble up the final product. Despite customer’s urgent request for delivery our professional post-processing team was able to assemble the parts and ship to the customers on time. The final prototype was checked carefully by our quality inspection team and the designated sales representative, Jack Zheng ,prior to shipping. At ProtoFab, we always make sure customers get personalized services.

Making a highly precise and true to CAD prototype like the AVA BYTE requires the collaboration between our professional team and the customer. After customer received the prototype with satisfaction, they are now asking us to do the design for manufacturing review. By choosing ProtoFab high quality prototyping services, you also gain access to comprehensive design assistance for manufacturing review, mass production services and true to design product customization. If you have a project that needs our help, please feel free to contact us!